Overview

Selecting commercial sink faucet parts necessitates meticulous consideration of project requirements, key features, and maintenance protocols to guarantee optimal functionality and longevity. Evaluating factors such as facility type, usage patterns, and compliance with standards is essential. Furthermore, implementing best practices for installation and regular maintenance is crucial for enhancing performance and ensuring user satisfaction in commercial environments.

Introduction

Selecting the right commercial sink faucet parts is not merely a matter of preference; it is a critical decision that can significantly impact the functionality and aesthetics of any facility. With the increasing demand for durable and efficient fixtures, understanding the essential practices for selection becomes paramount.

What factors should be prioritized to ensure that these components not only meet operational needs but also comply with safety and sustainability standards? Delving into the intricacies of this selection process reveals key insights that can lead to optimal choices for any commercial environment.

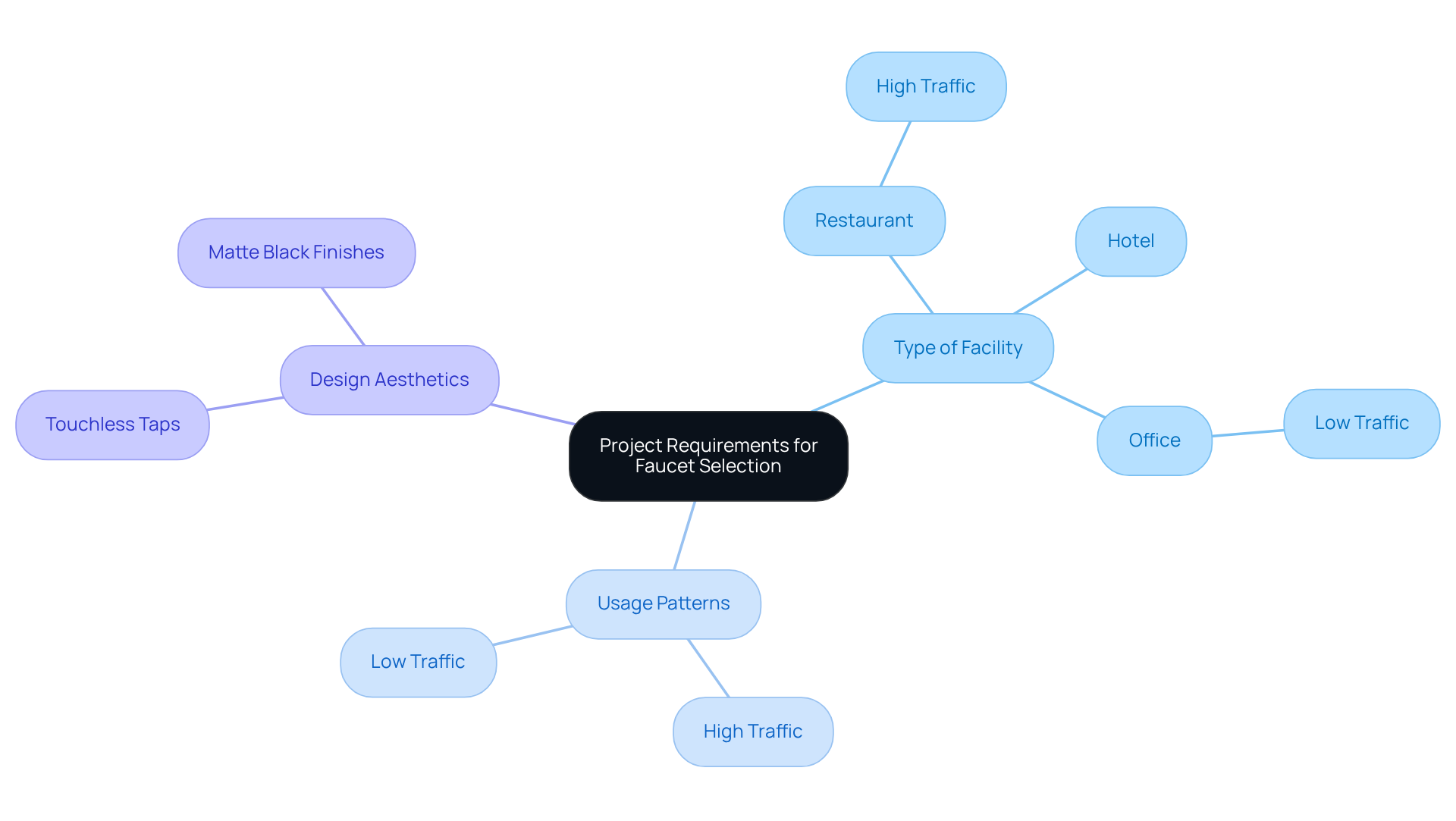

Assess Project Requirements for Faucet Selection

Selecting the right components, such as commercial sink faucet parts, begins with a thorough evaluation of your project's specific needs. Key factors to consider include:

-

Type of Facility: Each facility type—whether a restaurant, hotel, or office—has unique demands. For example, high-traffic locations such as airports or busy eateries require durable fixtures, including commercial sink faucet parts, that are also easy to maintain, ensuring they can withstand frequent use without compromising performance. As noted by Debadatta Patel, 'The demand for commercial sink faucet parts is rising in areas where sanitation and hygiene are essential, further aiding market expansion.'

-

Usage Patterns: Understanding the frequency of tap use is critical. A kitchen tap in a bustling restaurant must endure constant operation, while a restroom tap in an office may see less frequent use. This distinction significantly influences the selection of materials and design of commercial sink faucet parts. The market for commercial sink faucet parts was valued at approximately USD 5.8 billion in 2023 and is projected to reach around USD 9.3 billion by 2032, growing at a CAGR of 5.3%, underscoring the increasing demand for efficient fixtures.

-

Design Aesthetics: The fixture should seamlessly integrate with the overall design of the restroom or kitchen. Consider finishes, styles, and colors that align with the facility's branding and ambiance. For instance, touchless taps are increasingly preferred in healthcare settings for their hygienic advantages, while stylish matte black finishes are gaining traction in modern hospitality environments. Brent Otsuka emphasizes that "The Splash Lab is often the first choice for creating well-designed restrooms, underscoring its reputation for excellence in the industry."

By meticulously evaluating these project requirements related to commercial sink faucet parts, you can make informed decisions that enhance both functionality and design, ultimately leading to a more satisfying user experience.

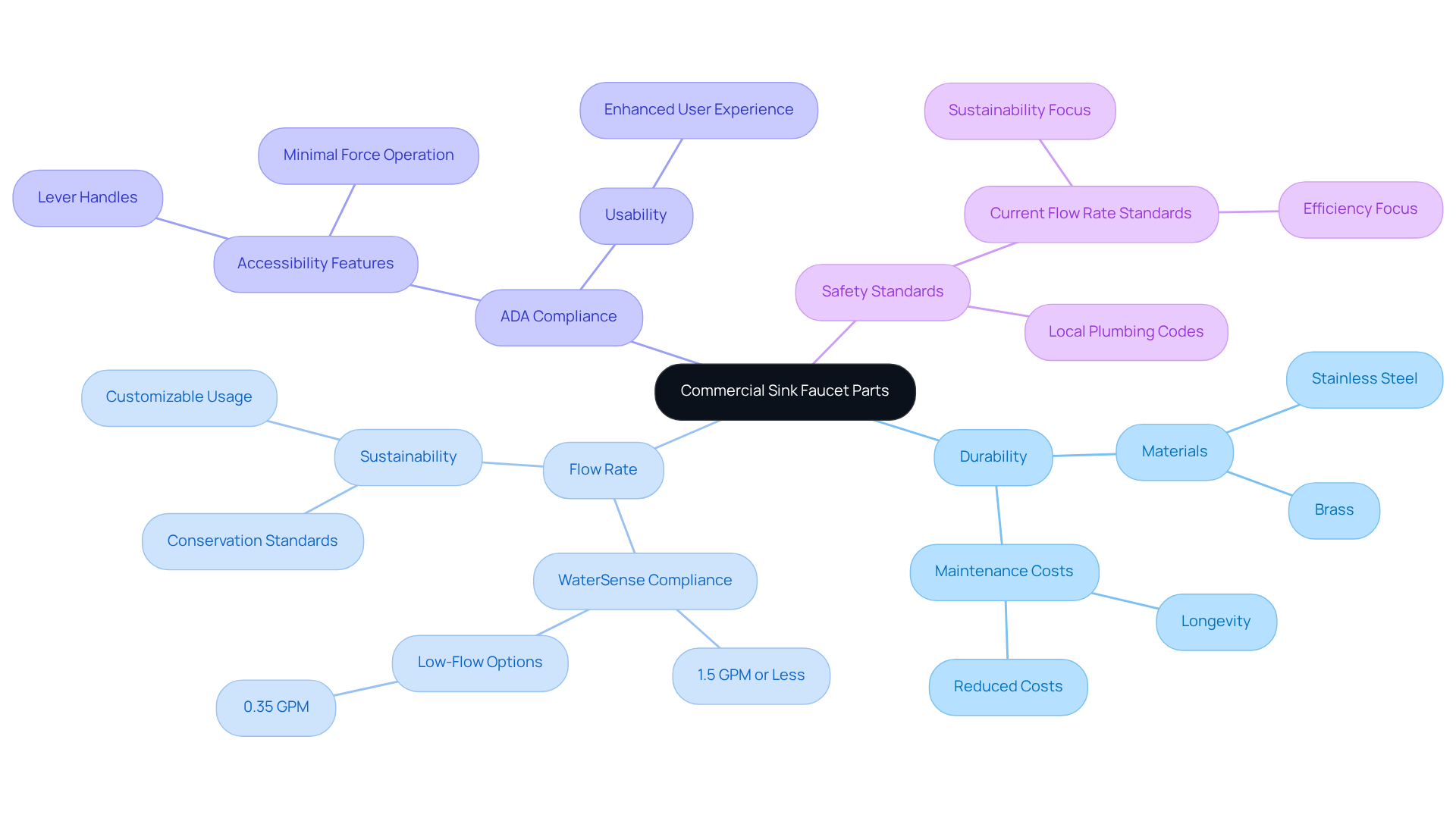

Evaluate Key Features and Compliance Standards

When selecting commercial sink faucet parts, it is essential to evaluate key features and ensure compliance with relevant standards:

-

Durability: Choose faucets constructed from high-quality materials such as stainless steel and brass, renowned for their resilience against heavy use. These materials not only enhance longevity but also reduce maintenance costs, making them ideal for high-traffic environments. For instance, the Lacuna Space project showcased how durable fixtures contributed to a well-designed restroom environment.

-

Flow Rate: Confirm that the flow rate aligns with facility requirements while adhering to conservation standards. Faucets should ideally maintain a flow rate of 1.5 gallons per minute or less to comply with WaterSense specifications, promoting sustainability without sacrificing performance. Contemporary fixtures such as the Verge series provide various low-flow alternatives, including designs that save water with 0.35 GPM, enabling customizable water usage that satisfies both efficiency and user needs.

-

ADA Compliance: Ensure that the taps are accessible to all users, including those with disabilities. Features such as lever handles that require minimal force to operate are vital for compliance with the Americans with Disabilities Act (ADA), enhancing usability for everyone.

-

Safety Standards: Familiarize yourself with local plumbing codes and regulations to ensure that the chosen fixtures meet all safety requirements. This encompasses understanding current flow rate standards for sink taps, which increasingly center on efficiency and sustainability.

By prioritizing these features and compliance standards, you can select fixtures, such as commercial sink faucet parts, that are not only functional but also safe and sustainable, ultimately enhancing the restroom experience in business environments.

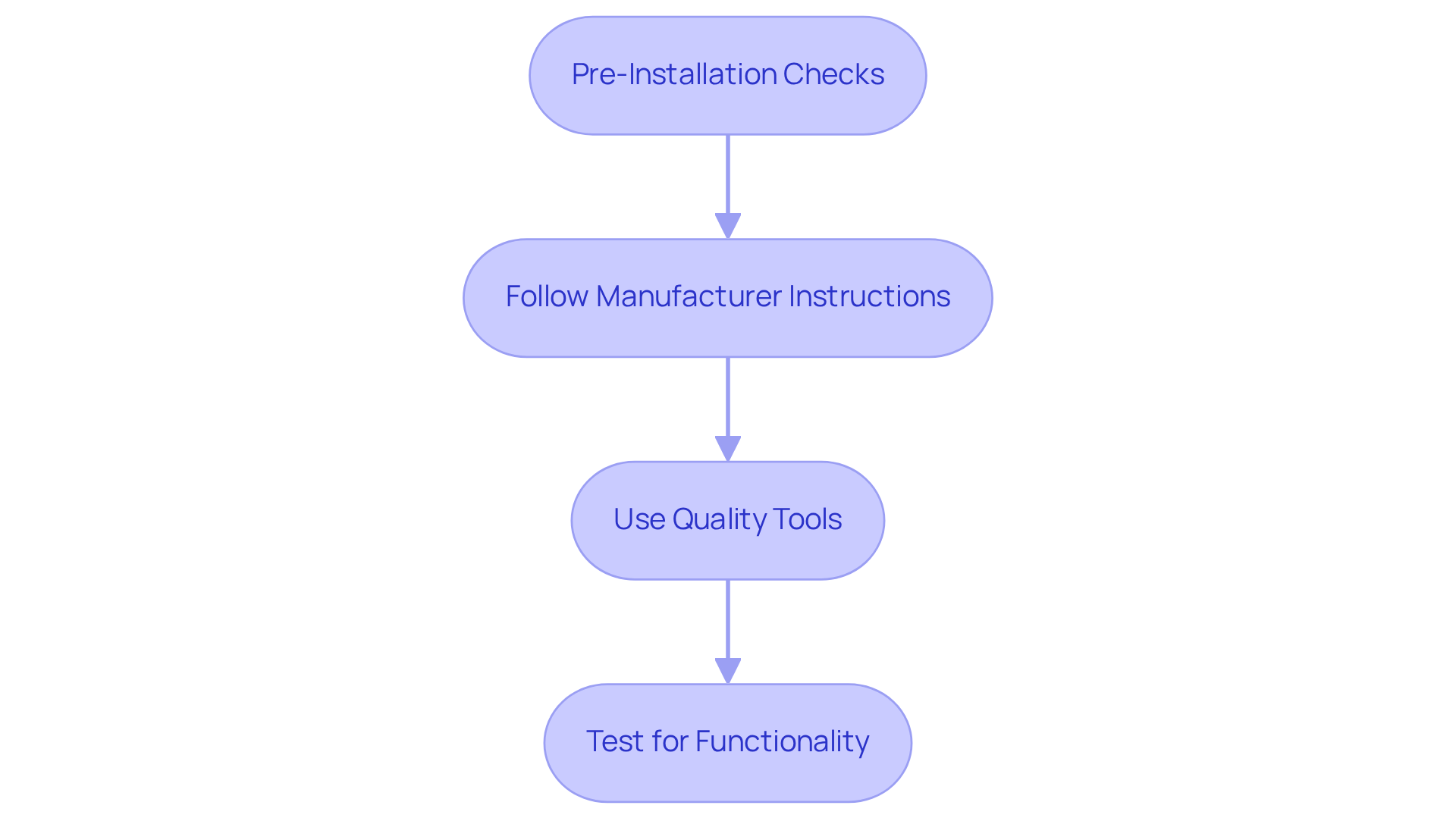

Implement Best Practices for Installation and Integration

To ensure the successful installation and integration of commercial sink faucets, it is essential to follow these best practices:

- Pre-Installation Checks: Prior to installation, verify that all plumbing connections are compatible with the selected faucet parts. Additionally, check for any existing leaks or issues within the plumbing system.

- Follow Manufacturer Instructions: Always adhere to the manufacturer’s setup guidelines. This includes proper sealing, alignment, and securing of all components to prevent leaks.

- Use Quality Tools: Invest in high-quality tools to facilitate the setup process. This investment can help guarantee that fittings are secure and minimize the risk of damage during installation.

- Test for Functionality: After installation, conduct thorough testing to ensure that the fixture operates correctly. Check for leaks, proper water flow, and ease of use.

By applying these best practices, you can significantly improve the reliability and performance of your water systems.

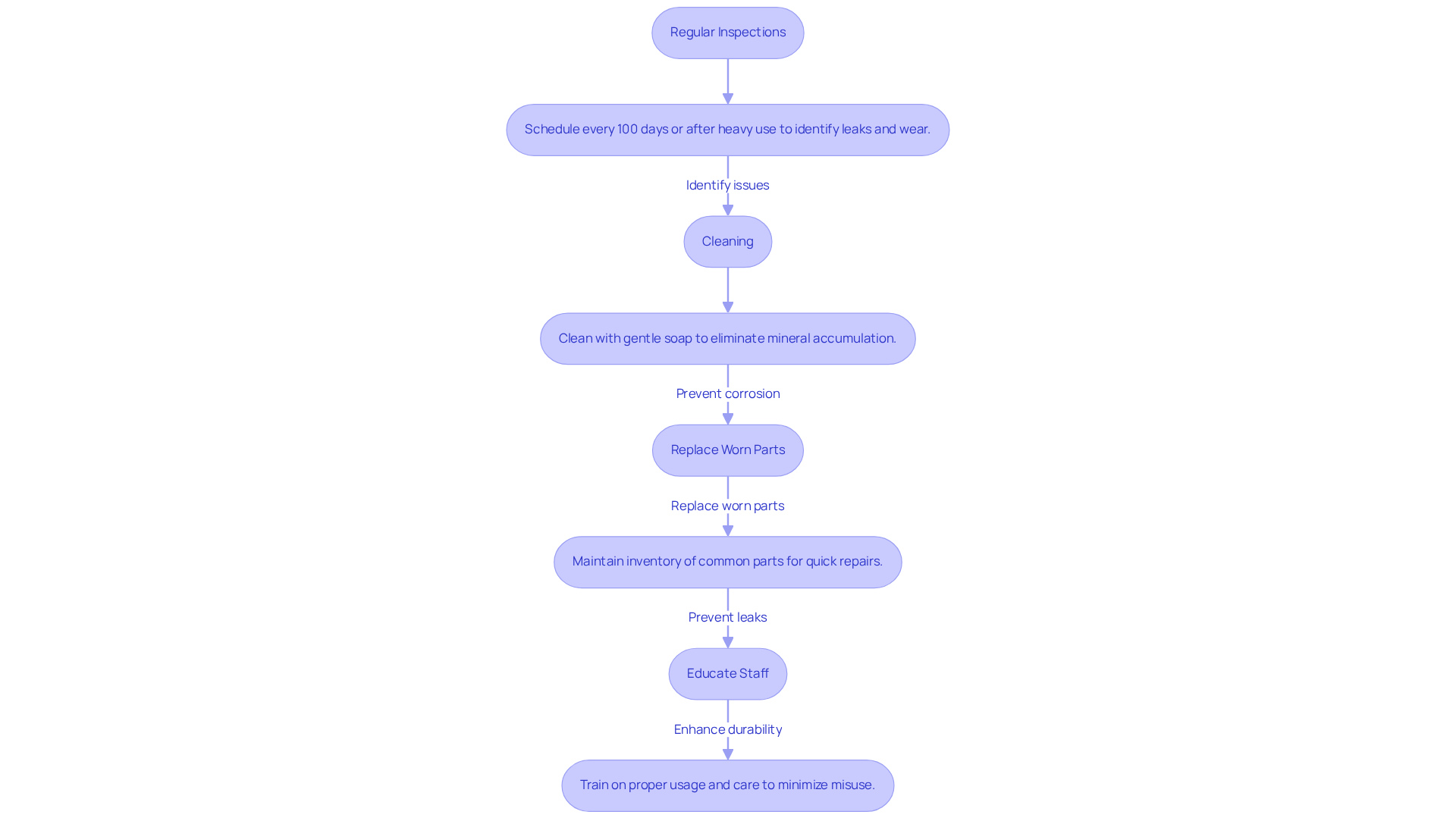

Establish Maintenance Protocols for Longevity

To ensure the longevity of commercial sink faucets, it is essential to implement the following maintenance protocols:

- Regular Inspections: Schedule routine inspections every 100 days or after heavy use to identify leaks, corrosion, and other signs of wear. Frequent issues such as drips and low fluid pressure can be identified early, avoiding major problems later on. Routine tap inspections can avert up to 40% of leaks.

- Cleaning: Clean taps regularly with gentle soap and liquid to eliminate mineral accumulation and avert corrosion. Mineral-rich liquid can greatly affect the durability of taps, so steering clear of strong substances that may harm surfaces is essential for preserving visual attractiveness in business environments.

- Replace Worn Parts: Maintain an inventory of common replacement parts, such as cartridges and washers, to facilitate quick repairs. Approximately 70% of tap leaks arise from worn-out O-rings and washers, making timely replacements essential for preventing water waste.

- Educate Staff: Train personnel on the proper usage and care of water fixtures to minimize misuse and ensure they are maintained correctly. Understanding the importance of routine checks can significantly enhance the durability and performance of the fixtures. Ignoring minor issues can lead to more significant problems, so using appropriate cleaning materials is essential.

By adhering to these maintenance protocols, you can enhance the durability and performance of your commercial sink faucet parts, ensuring they remain functional and aesthetically pleasing for years to come.

Conclusion

Selecting commercial sink faucet parts is a critical process that demands careful consideration of various factors to ensure optimal functionality and aesthetic appeal. By understanding the specific requirements of each project—including the type of facility, usage patterns, and design aesthetics—one can make informed decisions that enhance both performance and user satisfaction.

This article highlights essential practices encompassing:

- Evaluation of key features

- Ensuring compliance with standards

- Implementing best installation practices

- Establishing effective maintenance protocols

Durability, flow rate, ADA compliance, and safety standards are crucial elements contributing to the longevity and efficiency of these fixtures. Furthermore, following proper installation guidelines and conducting regular maintenance can significantly minimize issues and extend the lifespan of the faucets.

Ultimately, the significance of selecting the right commercial sink faucet parts cannot be overstated. By prioritizing thoughtful selection, adherence to best practices, and routine maintenance, facilities can create environments that not only meet operational needs but also promote sustainability and user comfort. Embracing these practices ensures that investments in commercial sink faucets yield lasting benefits for both the business and its patrons.

Frequently Asked Questions

What is the first step in selecting commercial sink faucet parts?

The first step is to thoroughly evaluate the project's specific needs, including factors such as the type of facility, usage patterns, and design aesthetics.

How does the type of facility impact faucet selection?

Each facility type—such as restaurants, hotels, or offices—has unique demands. High-traffic locations require durable fixtures that are easy to maintain to withstand frequent use.

Why is understanding usage patterns important in faucet selection?

Understanding the frequency of tap use helps determine the appropriate materials and design. For example, a kitchen tap in a busy restaurant will need to endure constant operation, unlike a restroom tap in an office which may see less frequent use.

What is the current market trend for commercial sink faucet parts?

The market for commercial sink faucet parts was valued at approximately USD 5.8 billion in 2023 and is projected to reach around USD 9.3 billion by 2032, growing at a CAGR of 5.3%, indicating increasing demand for efficient fixtures.

How should design aesthetics influence faucet selection?

The fixture should integrate seamlessly with the overall design of the restroom or kitchen, considering finishes, styles, and colors that align with the facility's branding and ambiance.

What are some design preferences for specific environments?

Touchless taps are preferred in healthcare settings for their hygienic advantages, while stylish matte black finishes are gaining popularity in modern hospitality environments.